The SPS Nanopositioning stage is high-precision, single-axis linear stage which provide the speed and positioning expected of a piezoelectric stage.

It build-in linear shaft motor, which has high positioning, low ripple and anti-cogging.

It used the cross-roller to guides.

Fixed the forcer to move the shaft could improve the reliability and life cycle in long-term operation.

Maintenance free and long lifespan! Non-contact motor design means no friction, so there is no sound or dust

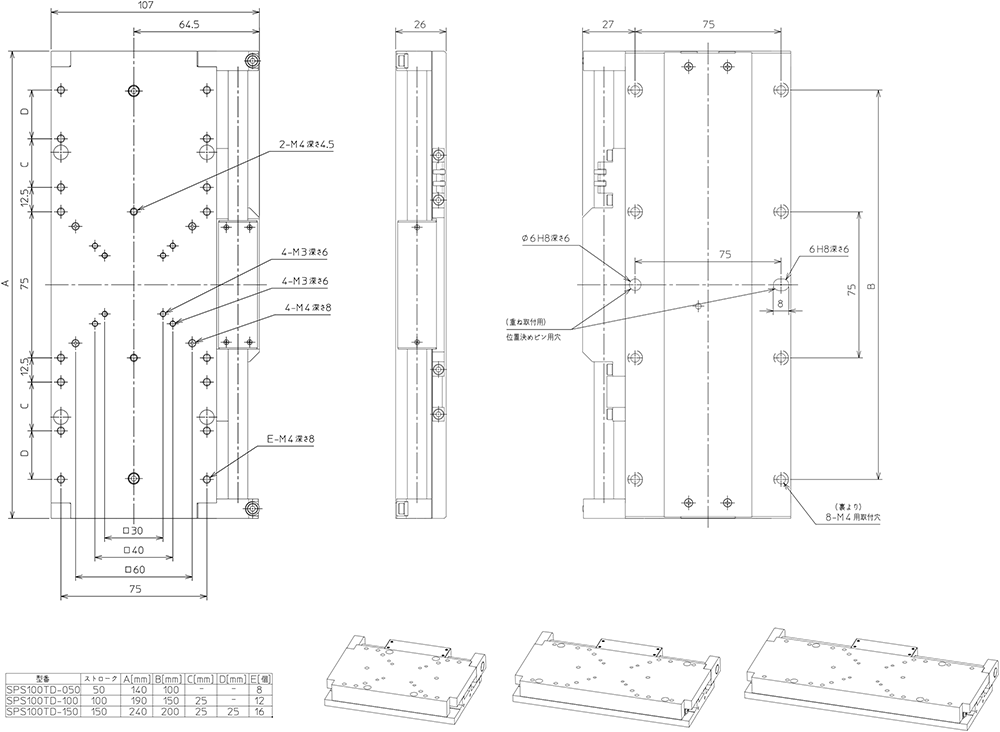

| SPS100TD-050 | SPS100TD-100 | SPS100TD-150 | |||||

| Stroke | mm | 50(±25) | 100(±50) | 150(±75) | |||

| Max. Stroke | mm | 51(±25.5) | 101(±50.5) | 151(±75.5) | |||

| Stroke | mm | 52(±26) | 102(±51) | 152(±76) | |||

| Motor Part Number | SX100T-DC-X0 | ||||||

| Driver Bus Voltage | VDC | 24~48 | |||||

| Continous force / current | N/Arms | 6.8N/1.1Arms | |||||

| Acceleration force / current | N/Arms | 27N/4.3Arms | |||||

| Linear guide | Cross roller with prevent guide rail misalignment | ||||||

| Encoder resolution | μm | Incremental 1/0.5/0.1/0.05/0.025/0.01/0.005/0.0025 Absolute 0.01/0.005 |

|||||

| Encoder interface | Incremental AB phase / Absolute(Panasonic) | ||||||

| Home sensor | Home sensor, limited sensor (only support incremental AB phase) | ||||||

| Dimension | mm | 140×107×26 | 190×107×26 | 240×107×26 | |||

| Motor Power/Encodedr cable length | mm | 1000 | |||||

| Moving mass | Kg | 0.57 | 0.75 | 0.93 | |||

| Total mass (without cable) | Kg | 0.97 | 1.33 | 1.7 | |||

| Load capacity *1 | N | 300 (30kgf) | |||||

| Repeatability *2 | μm | ≦±0.3 | |||||

| Straightness *3 | μm | ≦2/25mm | |||||

*1: The max. load capacity, please contact NPAT to check the moving condition.

*2: Repeatability

+/- 2 counts at sub 0.1 μm

resolutions

*3: Max. tolerance (um) / per each 25mm